Machines

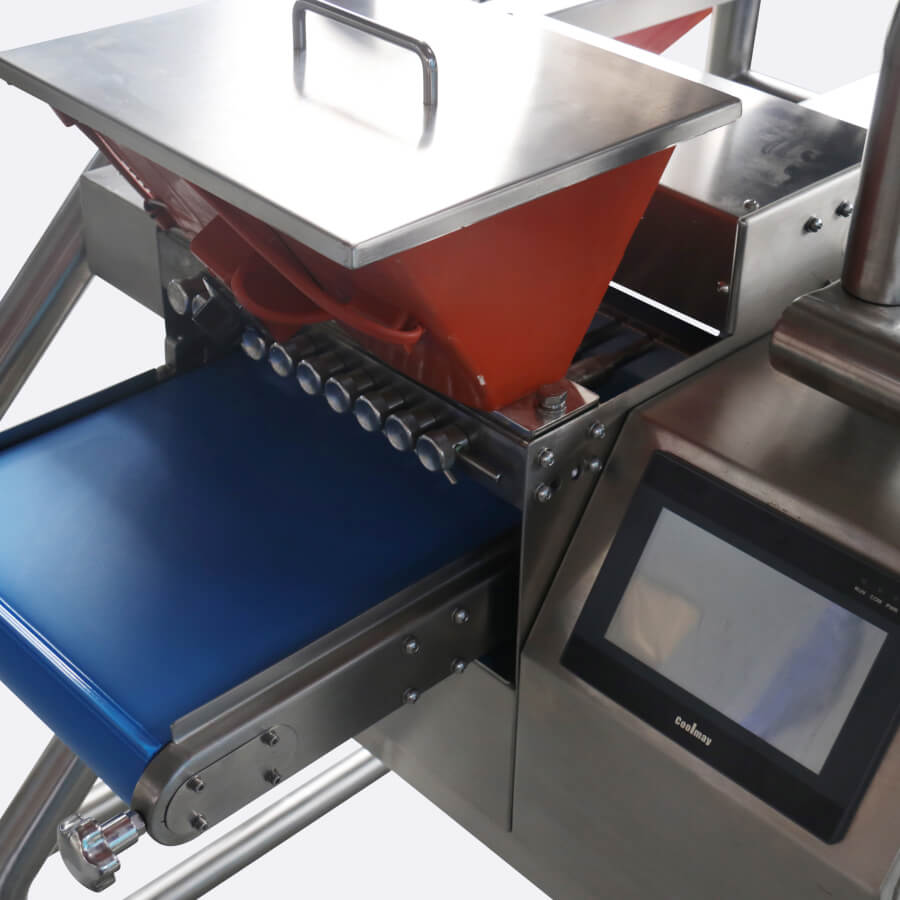

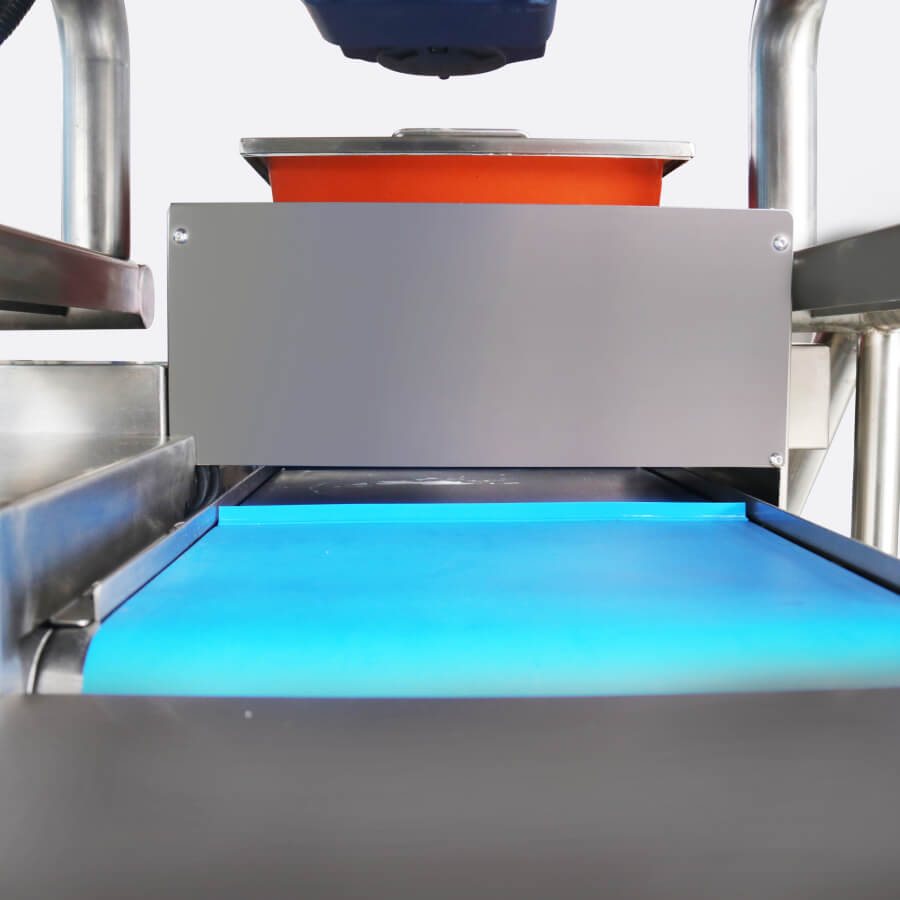

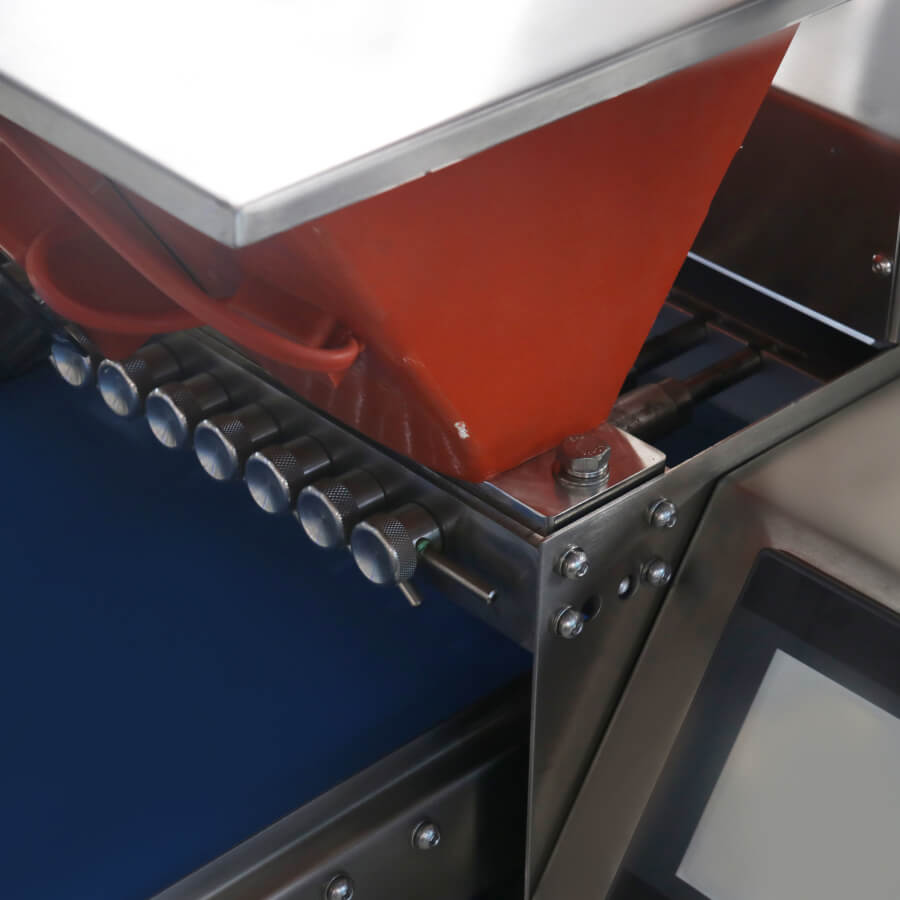

Mini Depositor with Cooker

Our compact gummy depositing system – Produces 18,000 pieces per hour!

The EVOCAN Mini Depositor with Cooker is designed for low-output production lines, creating various confectionery items like jellies, hard candies, lollipops, toffee, and more. It can produce up to 18,000 pieces per hour. It’s a practical choice where space is limited.

| Production Capacity | 18,000 deposits per hour |

| Electric Power Needed | 220V / 1hp / 60Hz |

| Room Temperature (°C) For Cooling System | 22~25 |

| Humidity (%) For Cooling System | 45 |

| Machine Dimensions: | 590 x 400 x 450mm(L x W x H) |

| Machine Weight (Kg) | 60kg |

Our compact gummy depositing system – Produces 18,000 pieces per hour!

Ask us about this machine. Our dedicated sales team would love to help you find the right gummy production solution!

3505 Cadillac Ave, Building K1, Costa Mesa, CA 92626. 657-267-0059

© 2024 EvoCan Systems | Built by Creatable